Aboult ANOLE

For mould manufacturer,invention and application of hot runner system solve a lot of problem in mould making aspects.from GE plastics (pp and os)to engineering plastics(abs,pc,nylon). Manu plastics materials can process through hot runner system. Whereas,this technology also bring a part of trouble for mould manufacturer,hot runner system leaking is one of the problems. How to find hot runner system leaking phenomena? When hot runner leaking,the bad condition is the production will be forced to stop.

difference between the hot runner system is the way of melt heating divided into internal and external heating. According to it’s name suggests,external heating system is heated plastic material in the external, the raw material run through the channel without obstacles. External heating system solves the problem of dead center in the melt channel.

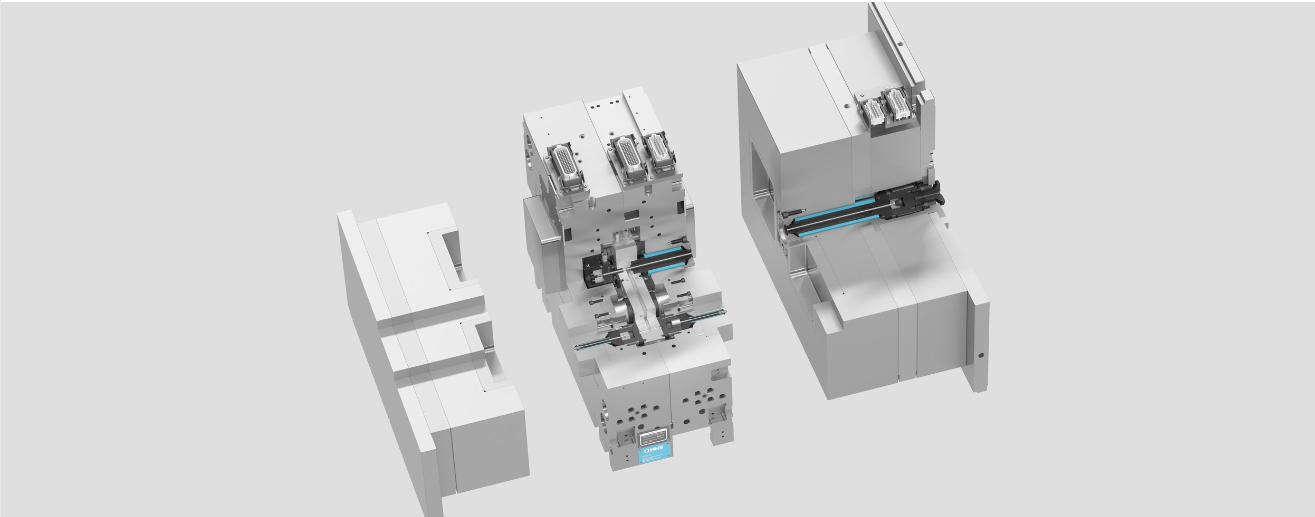

Hot runner system is the extend of injection machine and transmit the plastic material into each sprue in equally. In order to equally split the plastic material,the most effective way is to load a balanced manifold. This balanced mechanical can ensure each products balanced filling and avoid the flash and short injection phenomenon.Most hot runner system leaking is due to worker doesn’t operate and make according to design parameter. Leaking is usually happen between nozzle and manifold. As per normal hot runner system design,nozzle have a steel edge to ensure that the hot nozzle assembly height is lower than the actual groove of manifold. Purpose of design this size difference is to avoid damage the components when thermal expansion and this size difference is also called cold clearance. If don’t this cold clearance,thermal expansion will damage the nozzle edge.

Hot runner leakage is happen when system lack of seals. To ensure system seals(including nozzle and manifold),worker must heat the system arrive the manipulate temperature. Some unexperienced worker operate the machine when temperature is still low or forget open temperature controller.Leaking also happen when over heating.

So,it is very important to follow the hot runner design. Also,choosing a professional hot runner company is also important to a mould maker. Anole hot runner maybe is your best choice,we have many experienced engineer and designer. You will find more information about why hot runner system leaking or any hot runner using problem.