Aboult ANOLE

HOT RUNNER

——About ANOLE

Hot Runner Expert

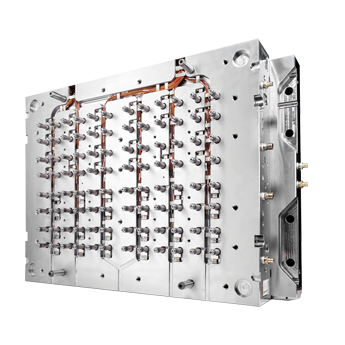

As for the hot runner company, ANOLE Hot Runner has 23 years of experience in hot runner RND and manufacturing. ANOLE Hot Runner has provided hot runner services for more than 200000 sets of various plastic injection moulds, and has accumulated a large amount of hot runner technology and experience from past service processes.

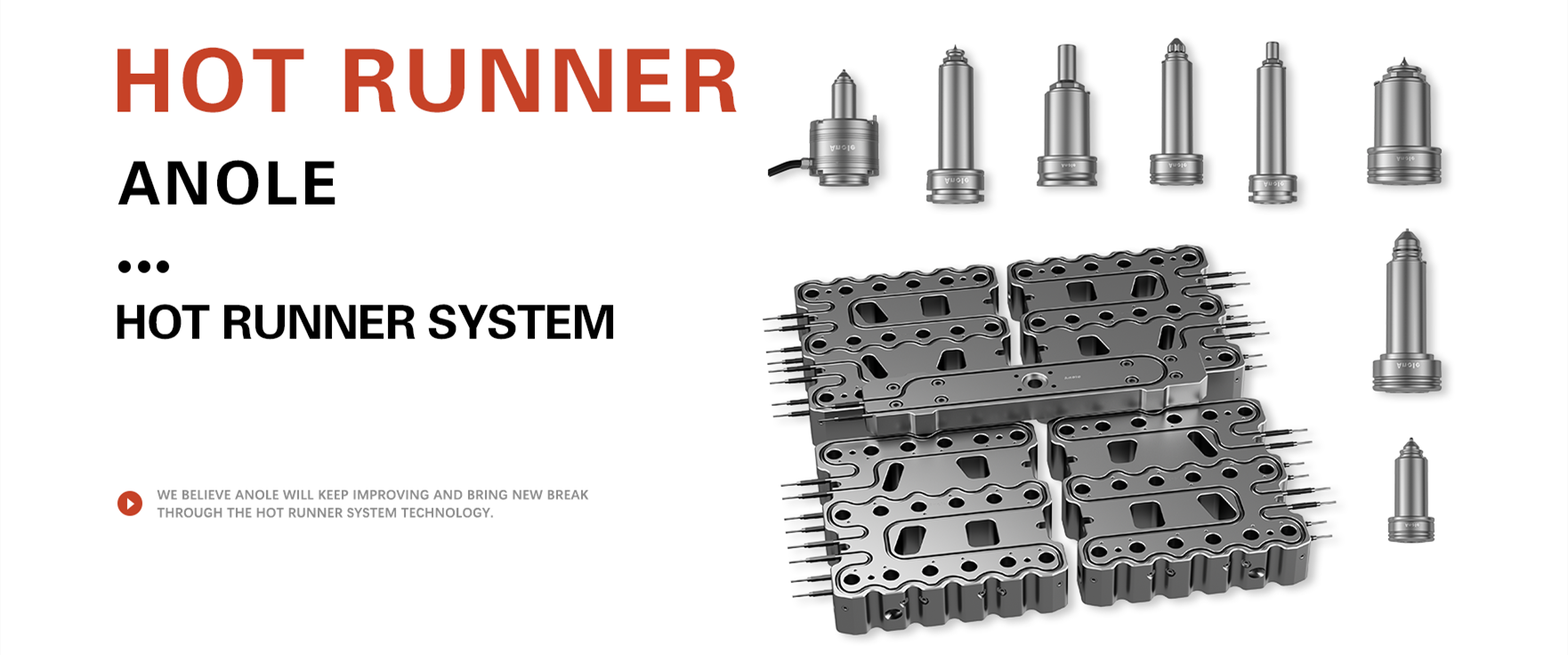

The Anole hot runner system adopts optimized and reasonable size design, high-quality high thermal conductivity, and German heating elements to ensure fast heating and accurate temperature control. It has a wide injection temperature range and can be easily molded at very low temperatures.

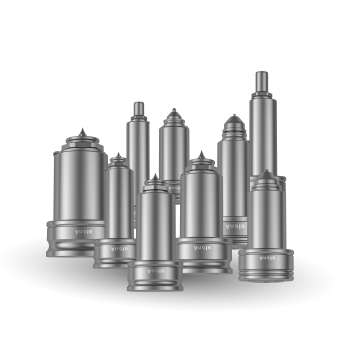

Anole hot runner nozzle series includes pin point gate nozzles, straight gate nozzles, valve gate nozzles, etc. Made of selected high-quality steel and original heating elements imported from Germany. Fast heating, precise temperature control, and precise sealing size ensure customers can install and use it correctly.

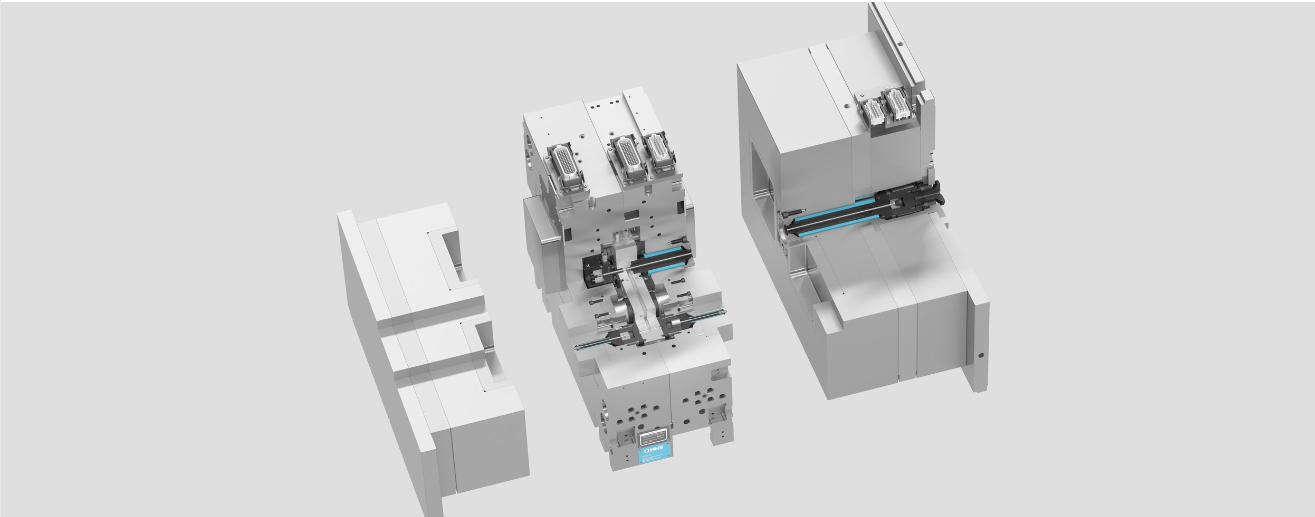

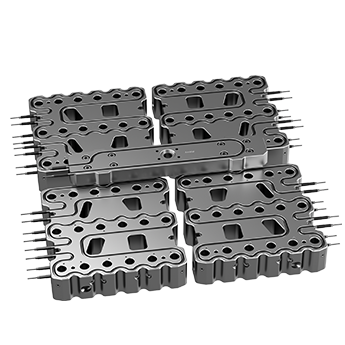

Anole's hot runner manifold plate series includes X, H, I, Y, K types, etc. The manifold is an important central component in the injection molding system. The manifold developed by Alone has the advantages of fast color change, easy heating, high precision, high temperature control accuracy, and proper flow channel balance.

ANOLE HOT RUNNER

ANOLE hot runner products line is complete, from pin point nozzle to valve gate nozzle, from vertical feeding method to lateral feeding method, from single point to 144 multi-tips, from single-layer hot runner manifold to multi-layer hot runner manifold..

Provide Better Hot Runner Service

In order to serve users quickly and well, ANOLE hot runner has established its own standards and established inventory. Standardized production, delivery, and service provide users with faster delivery, faster services, and lower costs.

Currently, ANOLE Hot Runner is building service networks worldwide, and we sincerely invite experienced and technical engineers to join the service network of ANOLE Hot Runner.

Hot Runner Innovative Technology

ANOLE hot runner continues to make breakthroughs in RND, especially in researching and innovating new materials, new structures, and new processes. ANOLE hot runner has formed a unique core competitive advantage in terms of performance, accuracy, pressure and temperature balance, and stability. After years of effort, the ANOLE brand has the representativeness in the hot runner industry in terms of technology.

Anole hot runner