Aboult ANOLE

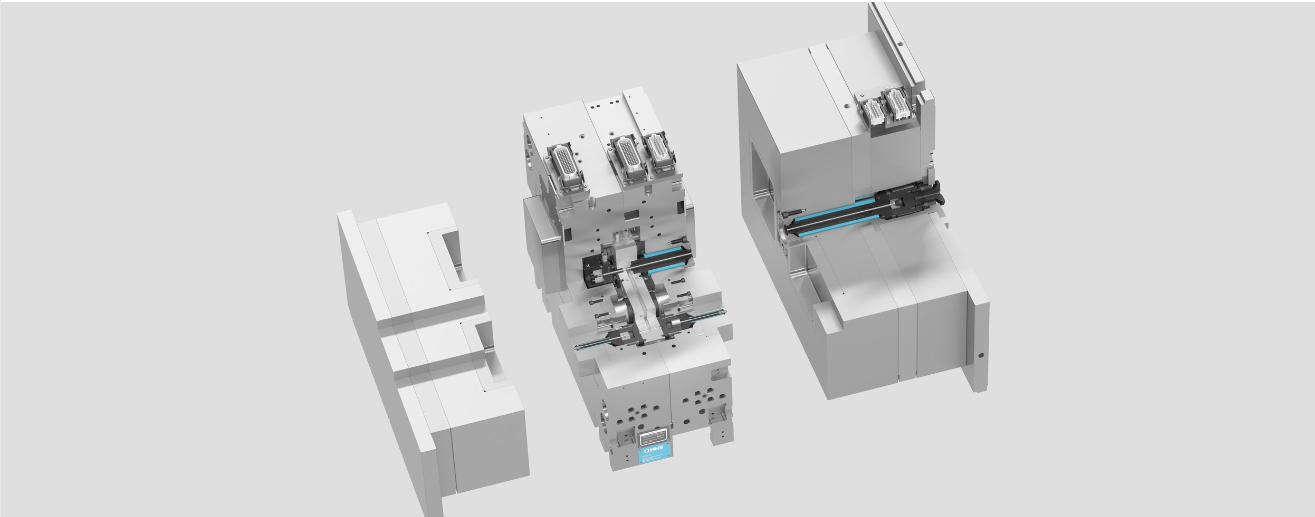

Ot runner mould design should think about not only hot runner flow route of plastic, cooling system and plastic processing technical problems, but also mould manufacture equipments and structure issue. In summary, plastic product injection points as following:

1. According to plastic material rheological behavior and runner, cavity flow resistance to analysis mold filling order. In the meantime, designer should consider melted plastic would be bypass flow or fusion again and air venting problem, analysis parting line position to decide sprue quantity and position.

2. On the basis of melted material performance figure, cavity shape and cooling system route arrangement, by analyzing we know pressure holding and in the course of cooling the mold part temperature behavior to solve mold parts shrink problem. As far as possible to reduce buckling deformation problem which is caused by temperature, pressure, crystallization and orientation inconformity.

3. Mold parts demold and core-pilling problem can be solved by experience and analysis.

4. Decide mold parts parting lie and cavity inlaying assembly.