Aboult ANOLE

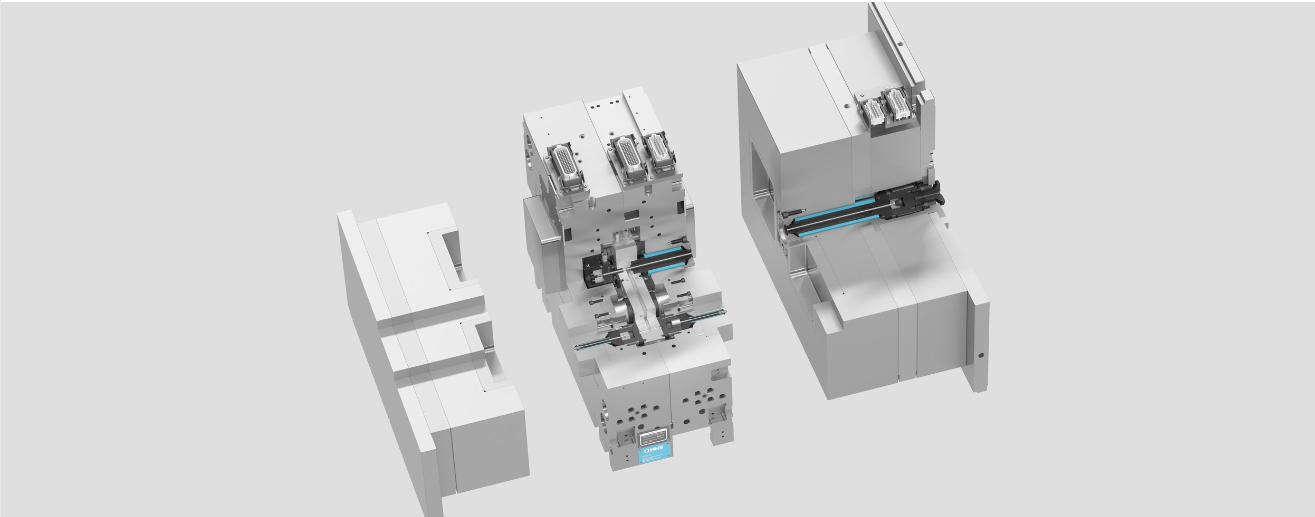

Hot runner mould technology development is a big change in plastic injection mould. In plastic molding, it has quite a lot of incomparable advantages.This is mainly because of hot runner mould has the following distinctive features:

1. Shorten the molding cycle time. Because hot runner mould is no limit to the cooling time of gating system.

1. shorten the molding cycle parts ,because there is no limit to the gating system, cooling time, stamping

2. Saving plastic material.

There doesn’t have cold runner in the hot runner mould ,so hot runner mould doesn’t produce scrap. This is very important for a project that plastic is very expensive,such as PC material. Hot runner technology is a effective way to reduce the scrap and save material.

3. Hot runner mould technology development has been successfully used in processing all kinds of plastic materials. Such as PP, PE, PS, ABS, PBT, PA, PSU, PC, POM, LCP, PVC, PET, PMMA, PEI, ABS/PC, etc. Any can use in a cold runner mold processing plastic materials can be used hot runner mould processing.

Hot runner mould technology development is increasingly important to electronic, automotive, medical, daily necessities, toys, packaging, building industry.Anole is a professional hot runner manufacturer ,we supply hot runner system,heating elements etc.