Aboult ANOLE

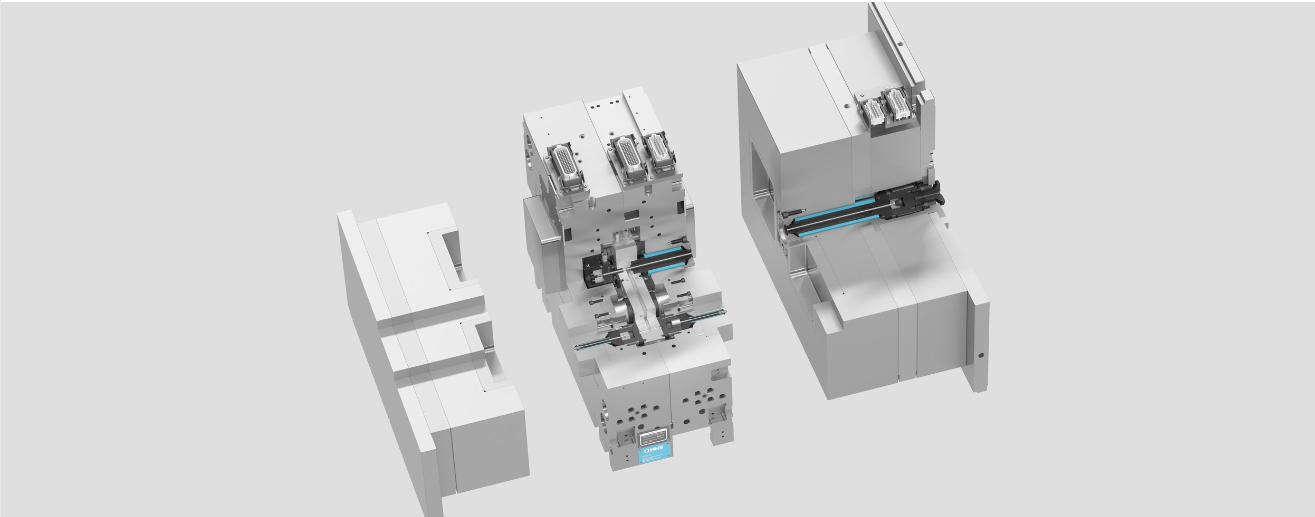

In the injection molding process, hot runner plays a very important role. Hot runner function can be seen in the below mentionded.

For example, in the injection molding production of ultra-thin (such as mobile phone battery cover), through the use of hot runner can easily produce the high precision, high quality products;For illiquid injection molding raw material, through the use of hot runner can obviously improve the liquidity of raw material, ensure injection production smoothly; For some large injection molded parts, such as automotive bumpers and door plank, TV shell, air conditioners shell and so on, through the use of hot runner, to make injection molding has become relatively simple. In multi-cavity mould, the product can not form if lack of hot runner. It can say that the hot runner is the best technology for the runner balance.

hot runner

For plastics processors, as long as there is a certain batch of injection molding production, using hot runner is very economic.

This is because the hot runner help enterprises eliminated gate in injection molding production.In most cases, the gate may not be reuse. Sometimes, the weight of the gate and products almost the same, if the traditional way of nozzle injection, means that the waste of raw materials and products used by as much as raw material. Extrapolate that using hot runner, you can save 30% ~ 50% of raw materials.

In addition, the hot runner also helps reduce mould wear, prolonging the life of the mould.