Aboult ANOLE

Today’s plastic injection mould is not simple machine and experience design. It is a theory design

that base on plastic materials, rheology and heat transfer. Hot runner mould get widely application

and occupy very important position in the mould industry.

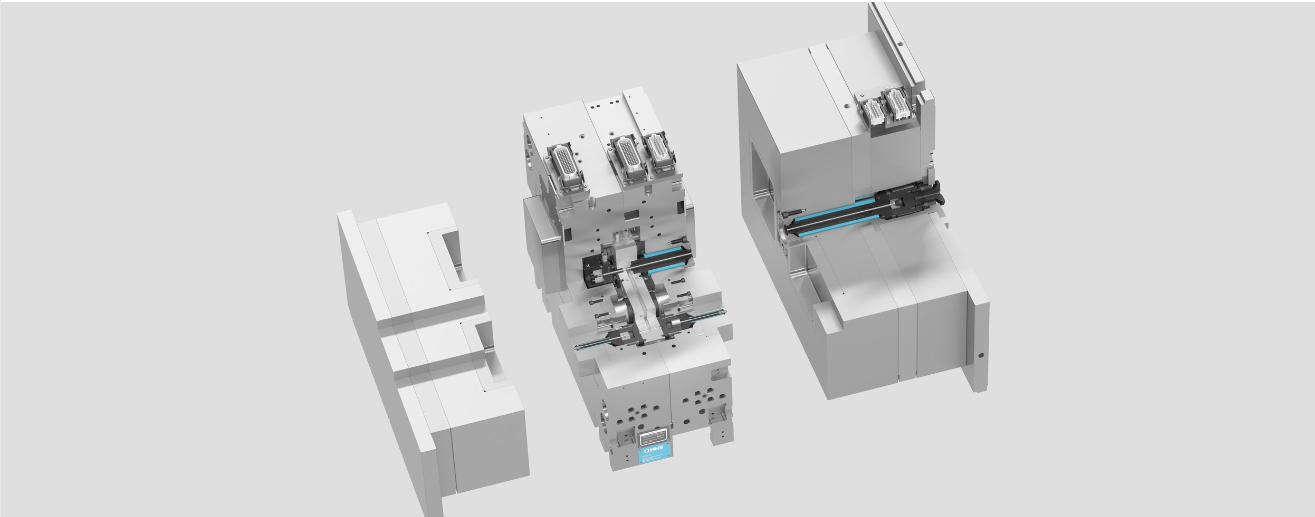

Stacking injection mould hot runner system major technology is

how to lead melt plastic into the manifold of mould center.

Please see the following picture,stack mould need a longer heating main runner.

Picture b show stack mould under open condition,melt plastic flow out from main runner entrance.

Therefore,there have two butt joint hot runner nozzle and butt joint is just parting line.

Stackable mould hot runner requirement is need two butt joint nozzle,some need control by switch.

But the room in mould center is limited,sometime we adopt feed in side mani runner.

stacking injection mould hot runner system

Moldmaster and D-M-E is participate in stacking injection mould hot runner system design and invest.

Also,this is one of hot runner system developing direction and hot runner system supplier goal.

Stack mould usually used to produce thin plastic products,like plastic hanger.

Relatively speaking,stacking mould thickness is thicker than normal mould.

In rating injection molding machine clamping force , it play in two times folded cavity number.

Anole hot runner is a experienced hot runner system supplier.

We could offer you a better stacking injection mould hot runner system.