Aboult ANOLE

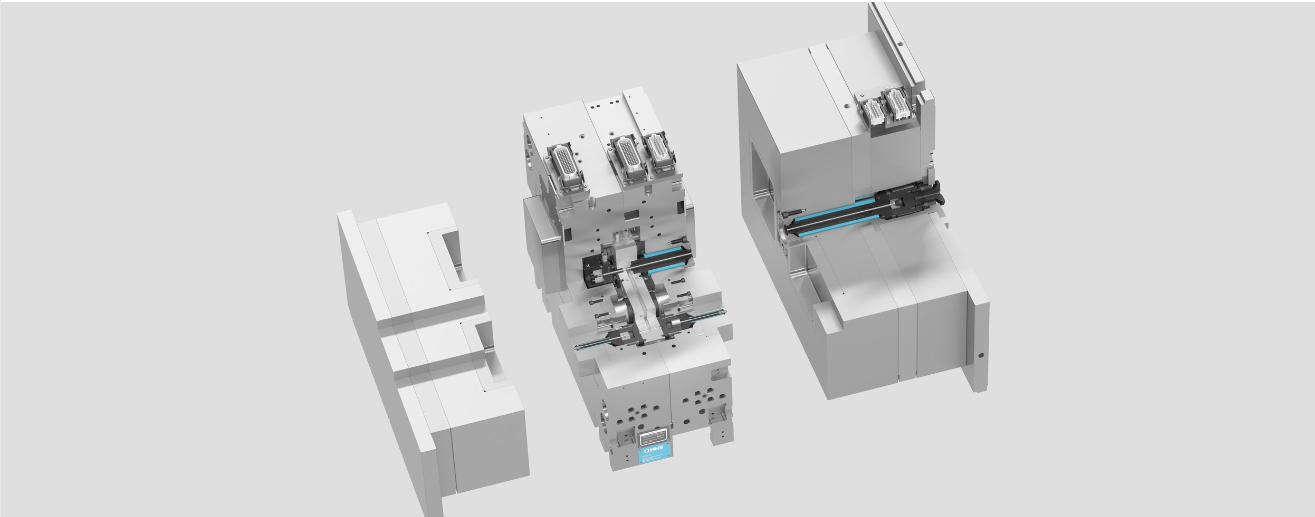

Hot runner mould production is extremely active in the developed industry country. Many foreign mould engineers have rich experience in hot runner system technology.In China,hot runner mould is still in infancy but it growing fast in recent years. Hot runner system is comprised of nozzle,manifold and hot runner temperature controller box. Hot runner nozzle can divided into pin point gate nozzle,direct gate nozzle,valve gate nozzle.

Why hot runner system technology is so hot in the mould industry? What is hot runner system injection strengths?

At present,hot runner mould is receive great popularity in the developed industry country and regions. Hot runner system injection strengths has following advantages:

Shorten plastic parts molding cycle

Hot runner system advantages is that it can shorten plastic parts molding cycle,because there is no limit to the gating system cooling time. Many hot runner mould cycle time for produce thin-walled parts can controlled under 5 seconds.

Saving plastic material

Hot runner system can save plastic material,that's mean do not produce wasted material. In fact,most international hot runner manufacturers get rapidly development in the expensive plastic material years. Hot runner technology is a effective way to save money and plastic material.

Reduce wasted products and rise products quality

In the hot runner mould molding process,molten plastic is precise controlled by hot runner system. Plastic can uneven run into each mould cavity. In this case,we can get good quality plastic products. Many high quality products in the market is produced by hot runner,such as MOTOROLA mobile phone,HP printing,DELL netbook computer.

Automotive produce

Plastic products do not need fix gate.

Expand injection molding craft application range

Many advanced plastic injection craft is develop on the hot runner technology,such as PET pre-molding . For PET Preform mould,we usually use the valve gate nozzle to produce. Valve gate nozzle can improve the surface quality and with a good adaptability for material.