Aboult ANOLE

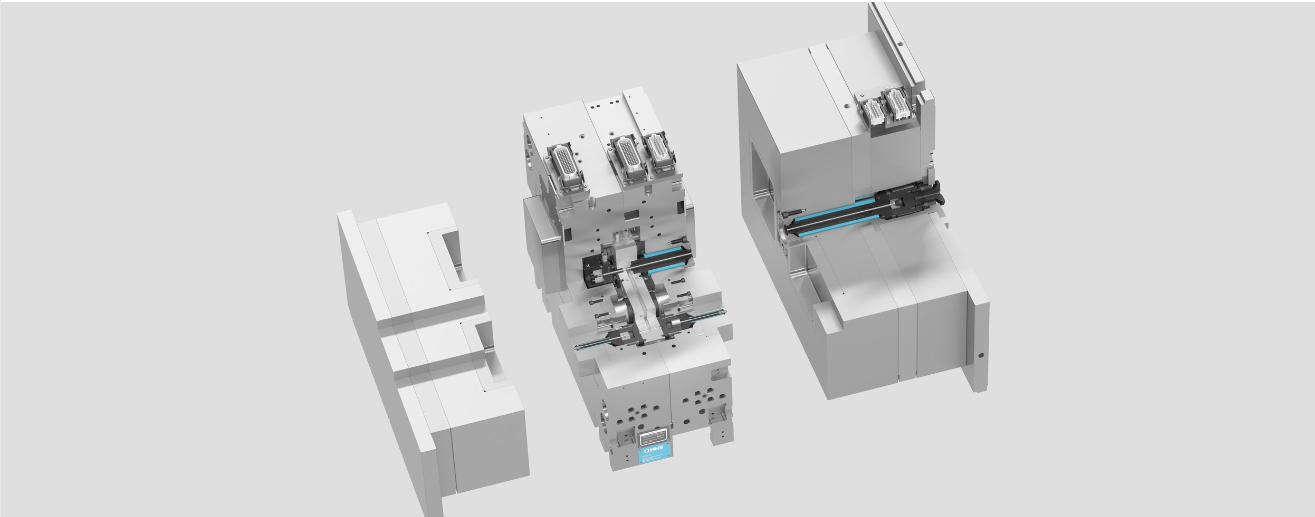

A good hot runner system request many factors to ensure during hot runner application.The hot runner temperature control and hot runner balance is the key factor for the plastic injection molding time.

1.Hot runner temperature control

Plastic temperature control is very important for the hot runner mould.Many production processing and product quality problem comes from bad hot runner temperature control.If possible try to select the hot runner temperature control system can realize respectively and multi-zone control to increase the flexibility of the use and strain capacity.

2.Plastic flowing balance control

Weld plastic in the hot runner system should keep balanced.Gate request to make the plastic fill to the cavities.For the components weight markedly different,we'd better make pouring gate dimension design balance.Otherwise,there will exist some components short of mould filling and pressure holding,some parts would appear excessive mould filling and pressure holding,flash,bad quality and etc.Hot runner gate dimension design should be reasonable.Small dimension will lead mould filling pressure over loss,Big dimension will lead the hot runner large volume,that makes the plastic in the hot runner system for a long time.Damaged material performance parts can not meet the use requirements after molding.