Aboult ANOLE

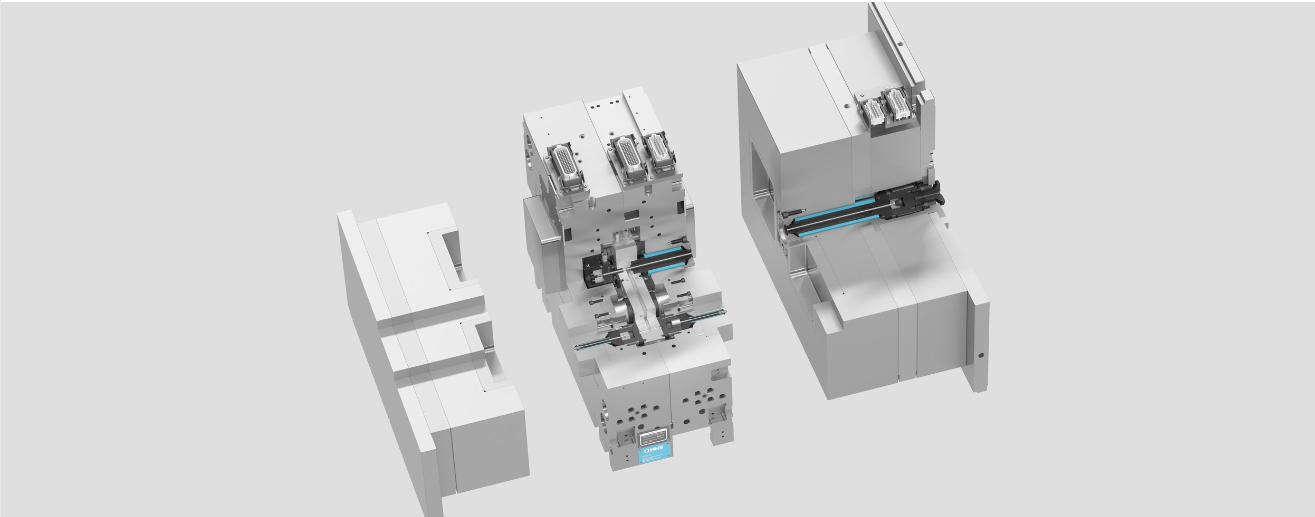

After finished hot runner injection mold designed and manufactured, the mould will be devoted to injection molding machine to produce. At that time, injection molding machine model choice is very important. Injection molding machine comes with automatic recyclability should suitable for hot runner system. When purchase manager choose injection molding machine should consider the following factors:

1. Thanks to hot runner advantage, many mould maker will recommend customer add hot runner system, hot runner mould will increase a runner plate, so the mould height will be increased, we must consider the injection machine’s max mould height.

2. When calculate the injection molding volume measurement, we should consider the compressibility of runner raw material.

3. Concerning the special of the hot runner mould, injection molding machine supplier suggest operator operate the injection act as continuous operation, adopt multistage start to prevent damage, numerous equipment to assure mould automatic operation, robot or mechanical arm is preferred. Such as:

a. Plastic products need insert tag or sheet to mould.

b. Take off plastic products or speed up ejection.

c. Control plastic products movement and reduce startup time accessory.

d. Before startup injection molding machine please heat the mould in advance.

e. Decrease install mould time, quicken the connection time of cooling water pipe, gas and electric circuit, hot runner temperature controller, etc.