Aboult ANOLE

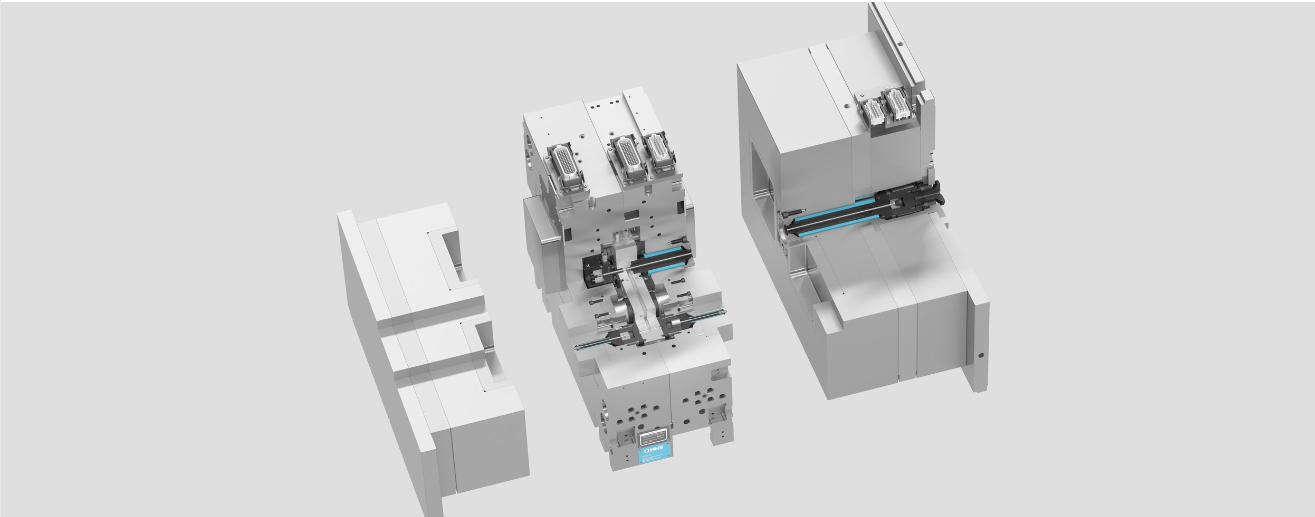

Over molding: which means two model plastic materials inject through an injection molding machine. It need injection and molding twice but only need once mould stripping mould. generally, this mould technology is also called bi-color mould.

Bi-color mould usually have two moulds, one is assembled on the machine fixed plate, and the other is on rotation plate. both of the two moulds core are the same. The only difference is on the cavities. After the first color injection over, open the mould and rotate 180 degree to inject second color. In the meanwhile, on the other side, first color is injecting. After second color injection finished, over molding products will be done. Later, every cycle time will have one-shot products.

During a production run of plastic inejection molded components, a number of different colored components may be required. The variety of color offered to the product designer, coupled with just in time manufacturing principle have increased the frequency with which color changes are required during a production run.

In order to change from one color to another, it’s necessart to remove all traces of the first color from the injection molding system. This is normally achieved by introducing the new color to the system in order to puch out the old color. The efficiency with which the change over from one color to the next can be achieved can be a critical cost factor.

Over molding hot runner system technology is an integral part of the mold, which can contain a sizable quantity of polymer in relation to the part. We are professional of the Bi-color hot runner system. Here we introduce Sino mould. sino moud is a bi-color mould supplier.